Manufaktur seit 1933

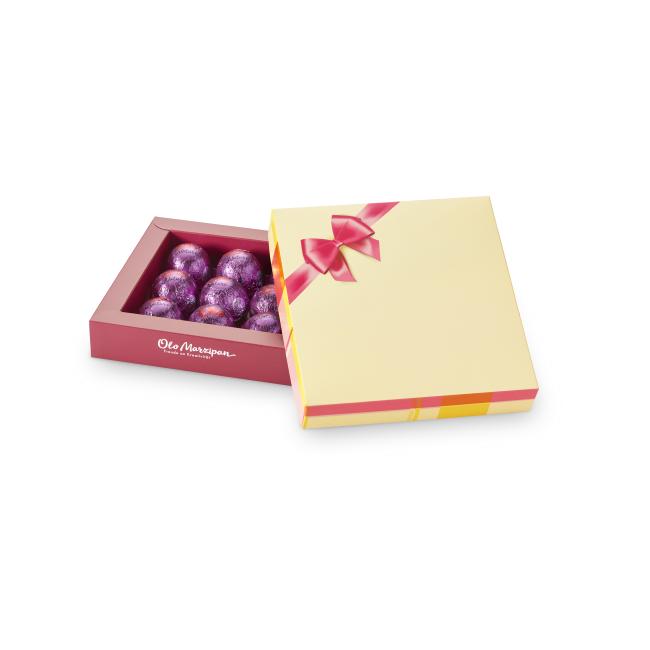

Willkommen in unserer süssen Marzipan-Welt!

Entdecke viele köstliche Marzipanprodukte - aber auch knackige Nüsse, feinstes Mandel-Nougat, den bekannten Berner Haselnusslebkuchen und verschiedene Backzutaten.

Alle unsere Produkte werden seit über 90 Jahren mit viel Leidenschaft und Freunde an Kreativität in unserer Manufaktur in Lyssach hergestellt.

Ein Blick hinter die Kulissen

Unsere Manufaktur ist der Ort, an dem Marzipankreationen zu Kunstwerken werden. Jedes Stück wird liebevoll von Hand gefertigt, um den höchsten Genuss zu bieten. Entdecke die Welt der süssen Magie!